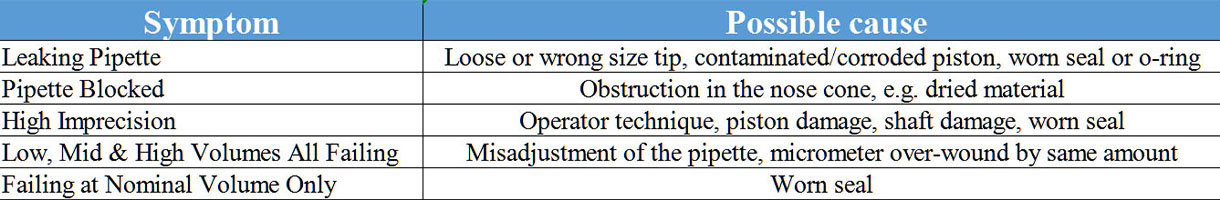

Some Common Pipetting Issues

Have you faced any of the above-mentioned issues during pipetting? If so, then spending a few minutes reading this article will benefit your pipetting operations.

Pipettes are precision instruments that demand attention to detail in order to produce consistent results. Preventive maintenance performed on a regular basis will help to minimize faults and keep your instruments in good Pipette Accuracy. Maintenance regimens might vary depending on the pipette's criticality, the types of solutions exchanged with the pipette, and the pipette's age. By following these 8 simple steps, pipette maintenance will be less difficult.

1.Remove Any Contamination From the Pipette’s Exterior

Place the pipette in a stainless steel or inert plastic tray, then wipe the outside with a decontaminant solution and dry with a lint-free cloth.

2. Examine the Pipette’s Overall Look

3. Take Apart and Clean the Pipette

Remove the tip ejector and separate the pipette's lower and top halves. As each component is withdrawn from the pipette, decontaminate it. Remove the seal and o-ring assemblies and visually inspect the components for wear and cracking,then clean the air passages with a long fiber-free swab dipped in cleaning solution (check the nose cone). Inspect the piston assembly for bends, corrosion, or cracks before rinsing it with distilled water and air drying it.

4. Change the O-Rings and Seals

5. Lubricant (if applicable)

Read the pipette's instruction manual.

6. Reassemble the Pipette and Test Its Operation

To ensure that the micrometer and tip ejector are moving properly, fully depress and release the pipette plunger 5 times.

7. Place the pipette vertically on the stand, adjust the spacer, and calibrate the micrometer to the nominal volume.

8. Check/Calibrate Pipette Performance